The Rise of Chip-on-Board LED Modules

Contributed By Electronic Products

2014-03-11

Until recently, a lighting designer looking to take advantage of the efficacy, longevity, and robustness of LEDs for his/her next luminaire was faced with some key challenges.

Among the toughest of these was the need to work out how many discrete LEDs were required to achieve the required “lumen density” (light output per unit area) for the product, and then design a circuit board that took into account the power- and thermal-requirements of this array without consuming too much space inside the lamp. Then the engineer needed to make sure that all of the LEDs in the group produced an identical color to meet the consumers’ expectations.

Today, a simpler solution is at hand. LED makers have introduced a new form of packaging for their high-power devices: the chip-on-board (COB) LED array. In supplying these units, the LED maker has done the work of matching the individual LEDs and designing a suitable substrate to carry the “light engine.” Better yet, COB LED arrays allow LED makers to take advantage of efficiency-enhancing techniques such as “remote phosphor”.

This article reviews the latest commercially available examples of COB LED arrays and considers how the sector will develop in the near future.

Drawbacks of discrete LED arrays

Although the performance of LEDs has improved dramatically, single devices still do not produce enough output for a mainstream lighting application. For example, a single 100 W, 120 V incandescent bulb generates 1,700 lumens (at an efficacy of around 17 lm/W). In comparison, a popular LED such as OSRAM's OSLON SSL 150 generates 136 lm (350 mA, 3.1 V, 125 lm/W). A lighting designer would need a dozen of these OSRAM devices to provide approximately the same output as the bulb.

This presents problems because of the physical space that the LEDs take up (typically measuring several square centimeters). Moreover, grouping LEDs into arrays also introduces challenges from illumination, optical, and manufacturing viewpoints.

Optimizing the quality of the light from an LED array is difficult. LED manufacturers sort LEDs into ‘bins’ of approximately the same color correlated temperature (CCT) and luminosity, but closely matching individual devices so that the consumer notices no difference becomes expensive and time consuming.

A second problem with a large array of LEDs is that the devices age at different rates. Many of the LEDs in a fixture could have plenty of life left while the others have dimmed, resulting in the consumer junking the unit. Finally, assembling an array of many LEDs is difficult and labor intensive, further pushing-up costs. (See the TechZone article “LED Packaging and Efficacy Advances Boost Lumen Density.”)

Eliminating assembly

To address the problems of designing and then assembling an LED array, LED makers now offer a modular solution in the form of a COB LED array. Such a device delivers both a ceramic package and a high level of integration.

COB LED arrays eliminate the need for lighting manufacturers to place individual LEDs on a printed circuit board (PCB) or have someone put them on a board for them. Another advantage that can ease the manufacturing process is that COB packages are suited to manual assembly. The COB can be stuck with epoxy or mechanically engaged to the heatsink without requiring a lot of engineering resources. (See the TechZone article “Consider Packaging for Performance Improvements, Cost Reduction.”)

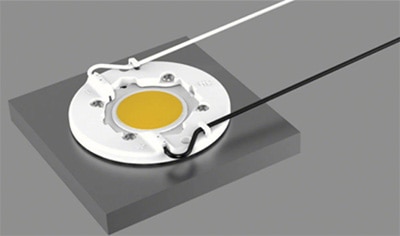

Molex offers a range of COB LED array holders for the Bridgelux and Cree products described below (Figure 1).

Figure 1: Molex’s COB LED array holders suit products from several major LED makers.

The advantages of COB LED arrays are not limited to assembly advantages; there are some optical pluses too. The devices typically use a “single emitting surface” in the form of a phosphor-coated disk. Conventional white LEDs use a blue LED and then Stokes-shift the light it emits using a phosphor comprising yttrium aluminum garnet (YAG) doped with the rare earth element cerium. The LED and phosphor are combined into a single package.

However, several researchers claim that so-called remote phosphor devices (whereby the phosphor is contained in a disk mounted some distance from the blue LED, the single emitting surface in the case of a COB LED array) improve efficacy and extend the life of the LEDs. (See the TechZone article “Remote Phosphor Offers Alternative to White LEDs.”)

Commercial COB LED arrays

Major LED manufacturers have introduced families of commercial COB LED arrays. Cree has recently launched a COB LED lighting array that it calls the XLamp CXA solution. The company claims this is a breakthrough technology that doubles the system intensity of spotlights compared to previous arrays. The company says that the first product released in the family, the CXA1520 LED, enables lighting manufacturers to create products that deliver the same luminosity as a 39 W ceramic metal halide device but using up to 50 percent less power.

The CXA1520 LED arrays deliver up to 3,478 lumens at 33 W (at 85°C). The product is available in CCTs from 2,700 to 5,000 K, and 70, 80, and 95 color rendering index (CRI) options.

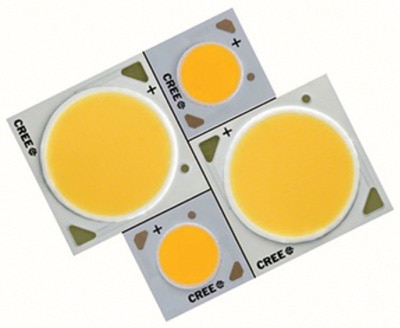

The CXA array features a uniform emitting surface that enables directional and non-directional lighting applications and luminaire designs (Figure 2). The product is available in two- and four-step color consistency, with a 19 mm optical source.

Figure 2: Cree’s CXA array features a uniform emitting surface.

Not to be outdone, Seoul Semiconductor offers its ZC series. The company says that because the ZC series is a COB device and the LEDs do not need to be surface mounted, lighting manufacturers can bypass the chip connection process, reducing unit costs.

Seoul Semiconductor claims that the use of “highly-reflective aluminum substrates” improves the brightness and prolongs LED life. The ZC series is available in 6, 10, and 16 W, which the company says are suitable replacements for 40 and 60 W incandescent bulbs and 100 W down lights, respectively.

The ZC series is available in CCTs from 2,700 to 5,600 K and minimum CRIs of 70 or 80, and can produce 2400 lumen (at a forward current of 480 mA). Similar to the Cree product, Seoul Semiconductor’s ZC series uses a uniform emitting surface for the LED array that measures 19 mm in diameter.

Bridgelux offers its ES Rectangle Array series (Figure 3) to compete in this sector. The company says that these compact high-flux-density light sources deliver uniform illumination without pixilation or the multiple shadow effect caused by discrete LED-based solutions. The latest generation of Luxeon COB LED arrays delivers from 700 to 3,000 lumens and a typical efficacy of 90 to 130 lm/W. Units are available with CCTs of 2,700 to 5,700 K and CRIs of 70, 80, or 90.

Figure 3: Bridgelux ES Rectangle Array series is available in a 19 mm version.

The company claims that the devices, which use a single emitting surface of 19 mm diameter, reduce system complexity and enable miniaturized cost-effective lamp and luminaire designs. Reduced thermal resistance allows for the use of smaller heatsinks or improved reliability of the lighting system when a larger heatsink is used.

The growth of COB

The cost-saving advantages of COB LED arrays compared with using discrete LEDs, designing a circuit board to carry them, and then assembling the unit are compelling for luminaire manufacturers. Such advantages are driving the dramatic growth of the sector.

According to the analyst firm Research & Markets, the COB LED market is forecast to grow at a compound annual growth rate (CAGR) of 40.71 percent over the period 2013 to 2018. Apart from the other advantages, the company says one of the key factors contributing to this market growth is the declining price of LEDs. Much of the increased demand is driven by mainstream lighting applications.

Even if the forecasters’ numbers are somewhat optimistic, the COB LED array sector is likely to grow significantly in the next several years. Expect to see more LED makers launch products in the very near future.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.