My Head is Spinning: Why So Many Op Amps?

Choosing the right or “best” operational amplifier (op amp) for a project can be daunting and overwhelming. Even if you restrict your search to a single vendor, there are likely tens of fairly similar devices to consider, often with new ones released as well. Vendor selection guides can help with broad categories (such as high speed, precision, high voltage) but even these divisions overlap and have ambiguities.

So, why so many op amps? A cynic might say, “It’s because they can,” but that’s really not the reason. Each op amp variation and sub-variation can be costly, requiring changes in one or more factors of design, fabrication, test, qualification, production planning, order fulfillment, packaging, and more.

In contrast, an academic would say the answer to the question is obvious: “It’s because there’s no perfect op amp.” While that is technically correct, it’s not the reason either. In fact, you might not want the ideal op amp, with infinite bandwidth, zero noise, and no other “imperfections” as it is too much of a good thing. To use it in your application, for example, you might need to add an external filter to attenuate external noise from impacting the op amp, rather than relying on the limited bandwidth of the device itself.

The reason that there are so many op amps actually is a consequence of two factors. First, there’s the sheer diversity of applications. Second, there’s the eternal engineering issue of tradeoffs. In the case of op amps – as with so many other components – these tradeoffs are not simple yes/no questions but have subtleties and nuances of degree and priority.

Some applications will tolerate less desirable values for some parameters in order to get truly superior performance in the one or two that really matter in that situation. For example, a precision instrumentation circuit may really, truly need low offset drift over a wide temperature range and be willing to accept some additional dissipation to achieve that goal. Still, the question is always, “How much are you willing to give up elsewhere to meet your primary objective?” If you can get 10% better offset drift performance but at the cost of a 50% increase in some secondary specifications, is it worth it?

Of course, then there’s cost factor: although almost all applications are cost-sensitive, the issue is to what extent is cost a critical factor. If spending a few more cents gets a device with 10% lower noise, is it worth it? The answer is not in an academic textbook, that’s for sure.

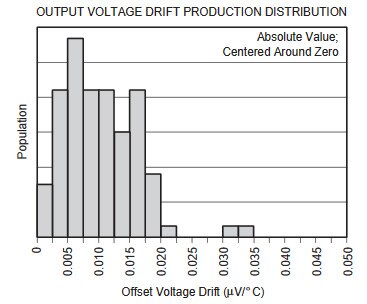

Consider two “zero-offset” op amps: the Microchip Technology MCP6V51 and the Texas Instruments OPA735. In addition to other differences, the Microchip device features initial maximum offset of ±15 microvolts (µV) and maximum offset drift of ±36 nanovolts (nV)/°C, (Figure 1). The Texas Instruments part has one-third the initial maximum offset at ±5 µV but about 50% higher maximum offset drift at ±50 nV/°C (Figure 2). So, which one is better?

Figure 1: The input offset voltage vs. ambient temperature is a critical specification in precision op amp applications. Here, it is shown for the Microchip Technology MCP6V51. (Image source: Microchip Technology)

Figure 1: The input offset voltage vs. ambient temperature is a critical specification in precision op amp applications. Here, it is shown for the Microchip Technology MCP6V51. (Image source: Microchip Technology)

Figure 2: The offset voltage drift is presented in a different way for the OPA735, but is clearly just a few nV/°C. (Image source: Texas Instruments)

Figure 2: The offset voltage drift is presented in a different way for the OPA735, but is clearly just a few nV/°C. (Image source: Texas Instruments)

The answer is deceptively simple, as it is in many engineering situations: “It depends.” In this case, it depends on how critical that initial offset value is when compared to its drift value, but it may be valid only for one specific application.

The decision on what and how much to give up in order to get what you want is a careful interplay of many factors and judgement, and that’s at the heart of the engineering challenge. It’s often a difficult decision since everyone at the design review may have a legitimately different point of view.

There are countless sets of different application priorities, relative weightings, and the “what you give up to get what you want” decisions that can be made. The good news is that the wide range of choice facilitates finding a very good fit (in most cases). Still, the multiplicity of choices can be overwhelming, and that leads to two possibilities: the designers may just choose the first device that comes close enough, or will just go with a vendor and device used previously and with which they are most comfortable.

Ironically, despite the many op amps already available and constant flow of new ones, many designers, rightly or wrongly, end up going with the one they’re most familiar.

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum